Rebuilding Coleman® Single Burner Stoves

Rebuilding Coleman® Single Burner Stoves

Chapter One: Disassembly

1.1 Drain the old fuel. Unscrew the Filler Cap and pour the old fuel into an approved container for disposal. You can find a local hazardous waste recycling facility by doing an internet search.

1.2 Remove the grate. Use a #1 cross-tip screwdriver to remove the three screws securing the grate. Set the grate and screws aside.

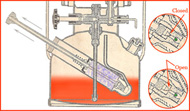

1.3 Remove the regulator assembly. With a 7/16” end wrench, unscrew the regulator’s fuel inlet connection from the shut-off valve assembly. Once free, pull the inlet tube down and away from the regulator (Figure 1).

Turn the regulator lock nut with your 1/2” end wrench to release it from the burner support. Once the nut becomes loose, pull the regulator and generator out of the stove.

Place the regulator in your bench vise and use the 7/16” wrench to remove the generator jamb nut. Rotate the regulator lever so that it is pointing towards the generator. Pull the generator tube away from the regulator and disengage it from the eccentric block (Figure 2). Set the pieces aside.

|

|

Figure 1 |

Figure 2 |

1.4 Remove the burner cap and rings. Spray the three screws in the burner cap with penetrating fluid and allow them to soak for a few minutes, then use a #0 cross-tip screwdriver to remove them. Apply a good downward force and stay square so they do not strip. Once all three are free, grab the burner cap and remove it.

Under the cap you will find the burner rings. Note that they alternate between flat and corrugated, with the flat filler rings on the top and bottom of the set. Put the screws, burner cap and rings aside.

1.5 Remove the burner bowls. The inner burner bowl can be difficult to remove, so take your time. Spray the connection at the center with penetrating fluid and allow it to soak for at least an hour.

Take a pair of channel lock pliers and open them up in a manner that will allow you to grab the outside of the bowl without much force (Figure 4). Gently squeeze the pliers while you attempt to turn it counter-clockwise. Do not squeeze too hard as you can bend it rather easily.

If the bowl will not release, spray it with penetrating fluid and walk away. I have seen this rusted connection take three days before the penetrating fluid broke it free. Exercise patience here and do not bend the bowl.

Once loose, unscrew the bowl from the Bunsen and set it aside. The outer burner bowl will now be free so take it off and set it aside. This will expose the burner support and the Bunsen (Figure 5).

|

|

Figure 4 |

Figure 5 |

1.6 Remove the Bunsen, burner support and collar. Spray penetrating fluid inside the collar, where the outer burner bowl screws connect to the fount. Allow it to soak for 15 minutes. Take a #1 cross-tip screwdriver and remove the three screws.

Remove the burner support and the collar together, then separate them. The Bunsen will be free now. Set these parts aside.

1.7 Test the check valve. If you can, now is a good time to test the function of your check valve. This is possible if the pump is working and the fuel filler cap holds pressure.

Turn the pump fully counterclockwise and give the fount 20-25 pumps. Press the pump all the way down and let go of it. Rest a finger lightly over the hole in the pump handle and see what happens. If your fount is pressurized and nothing happens, your check valve is working properly. If the pump raises your finger upward the check valve is leaking.

If it lifts your finger very slowly, you can probably get away with not removing the check valve, because the air stem is a positive stop safety for you. However, if it pushes your finger up quickly, you need to clean or remove the check valve.

1.8 Remove the valve. Use a small flat tip screwdriver to remove the center screw on the valve wheel and set it aside. Pull the valve wheel off the end of the valve. If the direction disc sticks to the inside of the wheel, slam it face-down on your bench once or twice to free it. Set the wheel and direction disc aside.

Gently bend the "loop" in the fuel line upward so that the bottom of the bend is above the fount (Figure 6). This is necessary because it needs to clear the fount when you turn it. Turn the fount upside-down and carefully place the valve body inside the jaws of your bench vise. Keep the bottom of the fount level as you snug down the vise.

What you want to do is unscrew the fount from the valve. Grab the fount firmly in both hands and gently squeeze. Hold it close to your body and slowly rotate it counterclockwise, ensuring that it stays level as you turn it. Use the filler cap and pump to aid in turning as necessary.

Once it comes free, release the vice and then unscrew the valve by hand. When the threads are free, pull it out of the valve (Figure 7). Set the fount aside.

|

|

Figure 6 |

Figure 7 |

1.9 Remove the fuel & air tube. Hold the valve in your hand and turn the fuel & air tube counter-clockwise with a 5/16” end wrench as shown in Figure 8. When the threads are free, pull the tube away slowly so you don’t lose the metering rod and spring that are inside (Figure 9). Set the fuel & air tube aside.

1.10 Disassemble the valve. Get the valve wheel from your parts box and place it back on the valve stem, then use it to turn the valve stem fully counterclockwise. Use a small wire brush and carburetor cleaner to remove the grease and dirt from the valve stem. Return the valve wheel to the fully clockwise position once the stem is clean.

|

|

Figure 8 |

Figure 9 |

While holding the valve wheel stationary, use a 1/2” end wrench and slowly turn the valve stem nut counterclockwise (Figure 10). Do not allow the valve stem to turn while you are doing this. Continue turning the nut until the threads release from the valve body. Now turn the valve wheel counterclockwise and pull the valve stem out of the valve body (Figure 11).

|

|

Figure 10 |

Figure 11 |

Remove the valve wheel and slide the valve stem nut off the back side of the valve stem. When the nut comes off, locate the small brass valve stem packing retainer (Figure 12). It will probably be loose and obvious, but it may stick to the valve stem nut where it can later fall off. Set this ring aside along with the valve stem nut, valve wheel and the valve stem.

|

Figure 12 |

1.12 Remove the old valve stem packing.

To remove the valve stem packing we will need to break it into little pieces. Look closely at the inside of your valve stem nut. You will note that the packing is pressed tightly against the threads (Figure 13). Set the nut down on your work bench with the large opening facing up. With a medium flat-tip screwdriver, angle the blade down inside the nut to where the threads and the old packing meet (Figure 14).

|

|

Figure 13 |

Figure 14 |

Press down hard on the screwdriver to “cut” into the packing. Slice the packing through to the threads, all the way to the bottom. With one cut into the packing, spin it around and do it from the opposite side. Continue until the packing breaks apart and you can completely remove it (Figure 15).

The old packing must all be completely removed from the bottom end of the nut. Use a wire brush and carburetor cleaner to remove it. Set the valve stem nut aside.

|

Figure 15 |

1.13 Remove the pump. Spin your Fount around and locate the pump cap.

If your lantern has two small screws securing the pump cap, remove them with a small flat-tip screwdriver. If your lantern has a metal clip holding on the cap, use that small flat-tip screwdriver and carefully pry one end of the pump clip out of the hole in the cap. Firmly grasp the free end with needle-nose pliers and guide it away from the cap (Figure 16). It will be very tight so be careful not to scratch the finish on your pump cap or fount.

|

Figure 16 |

Take some spray cleaner and wet the pump cap down. Allow it a minute or two to soak. Use a firm soft brush to remove the grease and oil from around the cap.

Grasp the pump handle and pull it up until you feel it reach the top. Now give it a few good upward tugs to unseat the cap from the fount.

It may require a little work to get it off. If you are unable to unseat the cap after pulling up firmly on the pump, you might need to pry the cap off the fount. Place the blade of a small flat-tip screwdriver under the bottom edge of the cap and gently lift, working your way around the cap until it comes free. Be careful not to damage the finish on the fount. Set it aside.

1.14 Disassemble the pump. Turn your pump upside down to see how the Pump Cup is being held on. You may see some variation of a hex nut, or a thin self-locking “push-on” nut (Figure 17). Also note the flat surfaces on the round pump shaft, near the bottom end. Use these flat areas to hold the pump with pliers or wrench.

If your pump is the style with a nut, use an adjustable wrench to turn it counterclockwise and remove. If it is the style with a push-on nut, place a small flat-tip screwdriver blade between the nut and the pump cup and carefully pry it off the end of the shaft. With the nut removed, remove the pump cup. Grab the outer edge of the backing plate with pliers and turn it counterclockwise to remove. You can now slide the return spring and pump cap off the pump. Set your disassembled pump aside (Figure 18).

|

|

Figure 17 |

Figure 18 |

Inspect the condition of the leather Pump Cup. If it just dried out but appears to be intact, you can probably revive it. If the leather has rotted, or has torn somewhere, it needs to be replaced.

1.15 Remove the fuel filler cap. Unscrew the fuel filler cap from the fount. I ALWAYS recommend using a new replacement cap whenever possible.

If you have an original one-piece cap that color-matches your stove, polish it with your fount and use it for display. When you use the stove, install a replacement cap.

If you have an original three-piece cap that color-matches your stove, polish it with your fount and use it for display. When you use the stove, install a replacement cap.

If you have a 500-series stove, there is not a replacement filler cap available for it and you will need to replace the insert gasket.

1.16 Disassemble the (3-Piece) fuel filler cap. This is the common filler cap with a panhead screw in the center. Reinstall the cap on your stove and tighten it down as much as you can with your fingers.

Note that there is a gap between the top of the cap and the bottom of the screw. Spray this junction with penetrating fluid and wipe away the excess. Allow it to sit for a few minutes.

Locate the flat tip screwdriver that best fits the center screw in your filler cap. Place the blade in the slot, aligning the screwdriver squarely down on the center screw. Apply firm downward pressure and attempt to turn the screw counterclockwise. If it comes free, remove it and set it aside.

If it seems to slip as you turn the screw, the fuel filler cap is not tight enough. Re-tighten the cap with your fingers and try turning the screw again. You can also tap lightly on the handle of your screwdriver with a wrench or small hammer a few times.

If the screw will not come out after hand-tightening three or four times, you will need to use pliers. Wrap a rag around the filler cap and gently approach it with slip-joint pliers. Be very careful and don’t scratch the fount as the jaws turn. Be gentle on the squeeze but don’t allow them to slip either.

Once you finally have the screw out, loosen the filler cap and remove it. You should find the Insert still sitting on your stove. Pull it off and set it aside.

1.17 Remove the air stem. With the pump removed from the fount you can see the air stem down inside the pump cylinder. Use needle-nose pliers to turn it counter-clockwise until loose (Figure 19). Use your fingers to continue turning, then remove. Set the air stem aside.

|

Figure 19 |

1.18 Test and/or remove the check valve. As I stated previously, you do not want to remove the check valve unless you need to. If you were able to test the valve earlier and know that it is good, you are done.

If you were unable to test it, you can do a simple test now. Clean the outside of the pump cylinder well, the place your mouth around it (yuk!). Blow into the fount, then try to pull air out of it. If you can't pull air out, the check valve is probably working just fine. You will be testing it again during re-assembly so if you have a problem you can deal with it then.

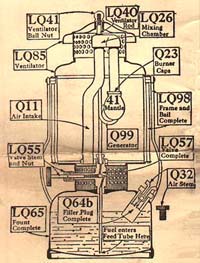

The location of the check valve is shown in Figure 20. If you need to remove it, please visit the page on how to do this.

|

Figure 20 |

Congratulations! You’ve finished tearing apart your stove!

|