Rebuilding Coleman® Two or Three Burner Stoves

Rebuilding Coleman® Two or Three Burner Stoves

If you are not mechanically inclined or are not comfortable working on fueled appliances, I encourage you to send your lantern or stove back to Coleman® for repair. Click here for more information.

Access to and use of this information constitutes your agreement with our Terms and Conditions. The material presented here is for informational purposes only.

Forward. These instructions were written specifically for Coleman® two and three burner camp stoves, but they can also be used to repair other stoves like Hot Plates, Air-o-Gas Ranges, Trailer/Cabin Stoves and a host of pressure stoves made by other manufacturers.

The location, fit and function of some parts may vary for different models, but you should be able to work through these differences if you understand what you are trying to accomplish.

The stove used in this instruction is a common Coleman® Model 413E, in the standard “good used” condition often found at garage or yard sales. Don’t worry if you see a photo of a lantern as some parts are the same and the lantern photos also apply to this lesson.

I encourage you to read the instructions in their entirety before starting. If you would like a better understanding of how lamps and lanterns work, visit the Old Town Learning Center.

Some of the photos you will see here are used in other rebuilding sections of the website. If you see a single or double mantle lantern, don't be alarmed. Many of the appliances have parts in common, and I'm just saving on photos and server space.

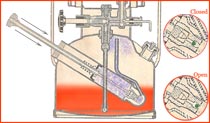

Scope of repairs. These instructions are written for a “full” rebuild, but not all stoves will require that level of service. You don’t want to remove the check valve unless you absolutely must, and you may not need to destroy a perfectly good valve stem packing. You will be cautioned before starting any step that may not be necessary.

If the stove has not been used in many years, or it is obviously worn out, I recommend you tear it apart for a full rebuild. If the stove is in near-new condition or was obviously well cared for by the previous owner, you might be able to get away with a good cleaning.

Replacement parts. Most of the parts can be cleaned and reused, but not all of them. Purchase the necessary replacement parts before starting work whenever possible.

Click here to view a parts listing for two or three-burner stoves.

Parts you should always replace, or at least have one spare:

1. Fuel Filler Cap, or the gasket.

2. Generator

Parts that may be required:

1. Pump Cup

2. Valve Stem Packing

3. Check Valve and Air Stem

Tools & Supplies. The following table shows the recommended tools and supplies you will need to follow these instructions.

| Fire extinguisher | Denatured alcohol |

| 5/16”, 1/2" end wrenches | Household cleaner |

| 7/16” Nut driver or 7/16" socket w/extension |

Cotton swabs |

| Small/med flat-tip screwdriver | Soft rags |

| Small hammer | Rubbing compound |

| Slip-joint and needle-nose pliers | Polishing wax |

| Small wire brush | Carburetor cleaner |

| Old toothbrush | Penetrating fluid |

| Rifle bore brush | Naval jelly |

| Bench vise | 0000 Steel wool |

| Small flashlight | Neatsfoot or a light oil |

| Length of small clear tubing | White vinegar |

| Eye protection |

![]() What happens if you get stuck? You can contact me via the Old Town Coleman Center Facebook page or you can email me at oldtowncoleman@gmail.com. I usually answer emails in the mornings and evenings as I am only semi-retired and still have a real job during the day.

What happens if you get stuck? You can contact me via the Old Town Coleman Center Facebook page or you can email me at oldtowncoleman@gmail.com. I usually answer emails in the mornings and evenings as I am only semi-retired and still have a real job during the day.

Pictures. Take photos of your stove before starting. During reassembly, you will be able to refer to the pictures should you have any questions about how something was positioned. “Before & after” photos of the rebuild are always fun to see, and we’d love to display one on our Spit & Whittle Club page. Good luck and keep that fire extinguisher close by!

Want to know

Want to know